Biorefinery extracts raw materials from waste wood

This week, chemical concern Avantium opened a trial plant in Delfzijl designed to convert wood chippings into glucose, a valuable raw material for the chemical industry. Avantium itself is developing the conversion technology.

Glucose contains the molecules of carbon, hydrogen and oxygen that are used to produce biofuels or components for PET bottles, for example. Currently, glucose is usually made from petroleum.

The Avantium plant uses wood chippings as raw material. Wood is composed of three constituents: cellulose, hemicellulose and lignin. The cellulose is already a compound molecule of glucose, and the hemicellulose a combination of glucose with other sugars.

Hydrochloric acid

To extract this from the wood, Avantium uses hydrochloric acid. That method has already been in use for some time, but Avantium has refined the technique to such a degree that it uses much less energy and water, and 99% of the hydrochloric acid can be re-used.

The lignin – the substance that gives wood its strength – remains and is used by the plant as a fuel for its own energy supply.

Dutch forestry organisation

The trial plant can process 20 tons of wood chippings a day, with about half of that being converted into glucose raw material. The wood chippings come from waste wood from forestry. To guarantee the supply, Avantium has entered into a partnership with the Dutch Forestry Organisation.

The trial plant is primarily intended to gain experience with the process and further optimise it. The plant is built on the site of AkzoNobel in Delfzijl, one of the customers for the glucose.

Subsidy

Ultimately the intention is to build a fully fledged factory that can process 130,000 tons of wood chippings a day. Avantium is investing 10 million euros in the trial plant, and has obtained a subsidy from the Groningen provincial authorities of 1.8 million euros. According to Avantium, one property of a trial plant is that it cannot run entirely commercially. But the fully fledged plant that is set to be operational in about five years is intended to be commercially competitive.

According to Avantium, its method has a major benefit relative to other plants that use wood as a raw material. The extraction of glucose makes full use of the material's chemical potential: from this raw material, all sorts of other substances can be made. Combustion, as currently occurs with co-firing in coal-fired power stations, just creates heat. Although converting it to biofuel creates a valuable product, there is no other benefit.

If you found this article interesting, subscribe for free to our weekly newsletter!

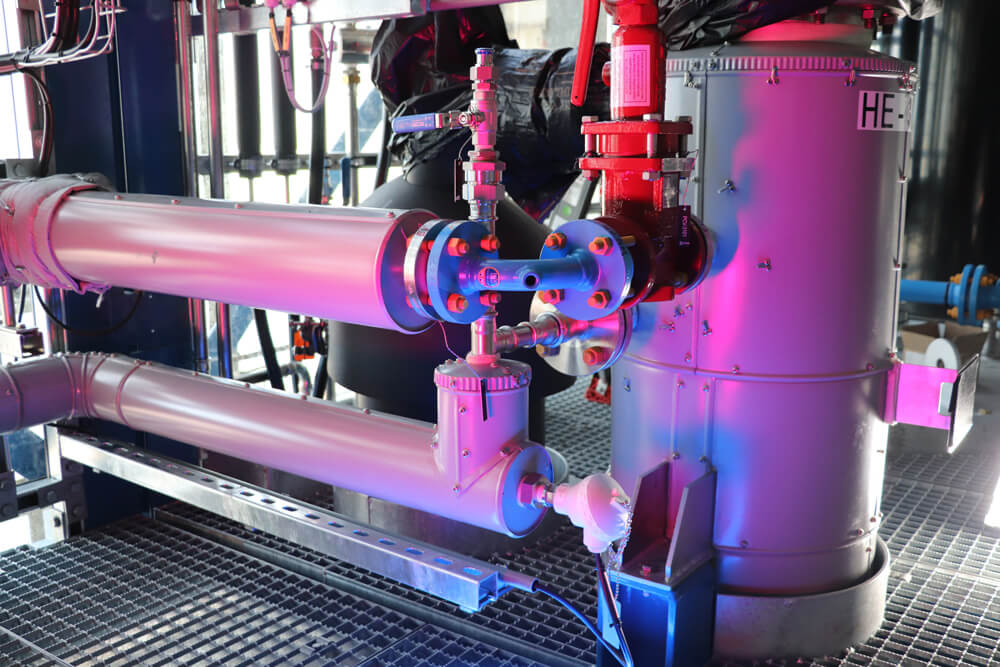

Opening photo: the chemical complex in Delfzijl. Photo: Groningen Seaports.

Meer artikelen

Hoe gaat het met de energietransitie in Europa?

Martijn Otten: Met techniek het verschil maken

Martine Stam: Water is de rode draad in mijn leven

Kirsten Steinbusch: Iedereen kan iets betekenen in de transitie naar circulair

Nieuwste artikelen

Hoe gaat het met de energietransitie in Europa?

Martijn Otten: Met techniek het verschil maken