3D printing using living cells

There is a smart trick that allows robust structures to be 3D printed while containing living cells. This was demonstrated by researchers from the University of Twente. The crux is to combine two miniature printheads, one of which generates droplets and the other a continuous jet of fluid. The two flows merge, creating a new material in the air.

Scientists have been dreaming for years of 3D printing structures that contain living cells. The medical world is particularly interested in this, for creating replacement sections of blood vessels, for instance, or for printing a piece of bone that has been destroyed in an accident.

Existing production techniques for ‘printing’ cells work by pressing a thick paste containing cells through a hole. The problem with this is that cells are not made to be pressed through a small opening. The cells often do not survive the massive shear forces exerted in this method.

Printheads at an angle

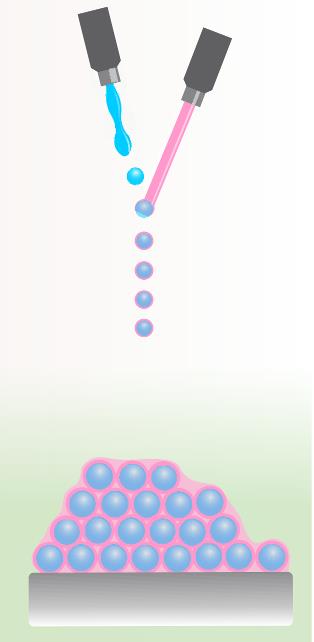

Researchers from the University of Twente in The Netherlands have found a way around this problem using an ingenious new printing technique. They came up with the idea of placing two small printheads beside one another at an angle. One produces a jet of fluid that is vibrated using piezoelectricity, causing drops to break off (see figure to the right) that are just a few dozen micrometers in size.

Researchers from the University of Twente in The Netherlands have found a way around this problem using an ingenious new printing technique. They came up with the idea of placing two small printheads beside one another at an angle. One produces a jet of fluid that is vibrated using piezoelectricity, causing drops to break off (see figure to the right) that are just a few dozen micrometers in size.

The second jet comes from the right and is aligned precisely to merge with the stream of drops. Because the pink fluid has a lower surface tension than the blue one, it flows around each blue drop. While still in the air, this process forms blue drops encapsulated by pink liquid that then land upon a substrate.

In this application, the cells are contained in the blue fluid. Each drop that breaks off contains a single cell. ‘We work with low viscous fluids, so cells easily survive our printing process’, explained Tom Kamperman from the University of Twente, one of the authors of an article in Science Advances, which explains the bioprint technique that he developed together with his colleague Claas Willem Visser.

All sorts of particles

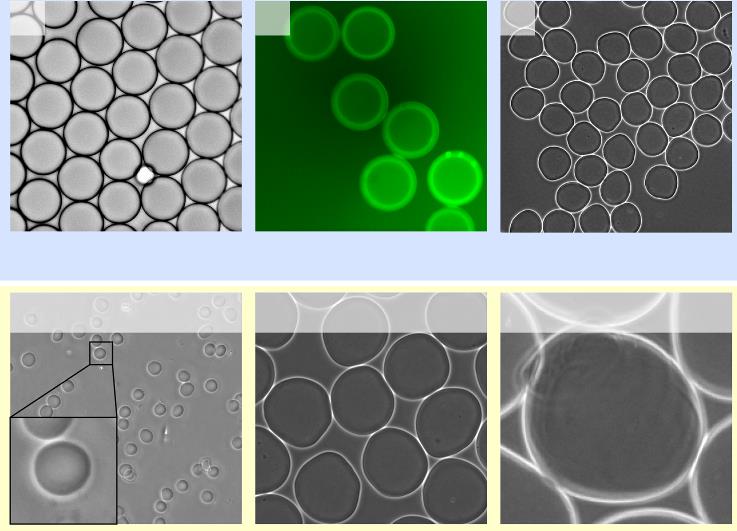

The researchers from Twente used their approach with the two merging jets to make all sorts of particles (also without cells): drops of water surrounded by a thin layer of oil (see figure below, upper left); hollow spheres of the binding agent alginate (upper right picture); capsules of alginate filled with liquid. And so on.

So various structures are possible, but also different shapes. For a start, making the liquid jets wider gives you larger spheres (see figure below, bottom row). The researchers have created particles with diameters varying from 20 µm to 300 µm.

By making the continuous jet flow faster, elongated particles can be created. Finally, the two printheads were placed closer together, with two continuous jets merging, creating microfibres.

Faster and easier

The new printing process has a number of benefits versus existing techniques, which are often based on microfluidic chips that lay down fluid drops. Apart from anything else, the process created in Twente is some hundred times faster. Microfluidic chips are no longer needed, making it easier for other scientists to use.

However, it should be noted here that although the new printing process has been demonstrated, it's still not ready for use by anyone wanting to fabricate biological materials. A number of further steps are required for this purpose.

Scaling up

One of these is scaling up the printing technique. ‘We want to place a number of these systems in parallel, so that you can lay down more material per unit of time. Another wish we have is drop-on-demand: we can now print continually, but to build structures, you must be able to switch off the printhead when necessary’, explains Kamperman. So the scientific research at the University of Twente continues. At the same time, they have set up a spin-off company that is working on making this technology commercially available: IamFluidics.

Tissue

Once the new printing technique has matured further, the research field of tissue engineering (building and restoring tissue) will probably be one of the first to benefit. ‘We have already managed to make spongy structures containing cells, which strongly mimic natural tissue.’

And stem-cell therapy, used to supply certain types of cell to specific parts of the body, can perhaps now become somewhat more efficient. Kamperman: ‘Currently if you inject stem cells, they tend to disappear quite fast, limiting the effectiveness of the therapy. We hope to encapsulate stem cells effectively in a hydrogel, so they stay in place for longer.’

If you found this article interesting, subscribe for free to our weekly newsletter!

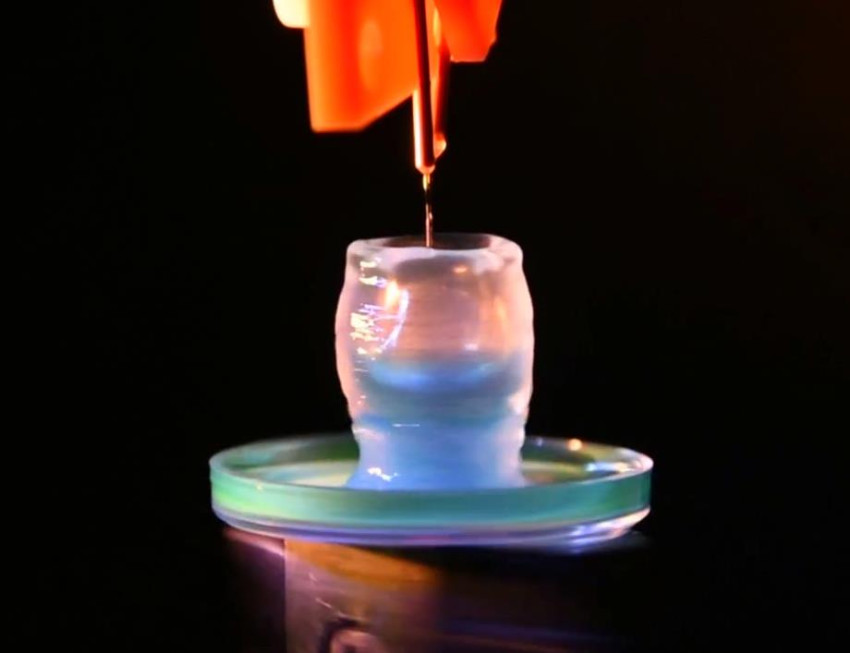

Opening image: Demonstration of 3D printing using the new technique. The hollow cylinder is made up of spongy material with living cells in the cavities. Image material Visser et al., Science Advances, 2018.

Meer artikelen

Hoe gaat het met de energietransitie in Europa?

Martijn Otten: Met techniek het verschil maken

Martine Stam: Water is de rode draad in mijn leven

Nieuwste artikelen

Hoe gaat het met de energietransitie in Europa?