3D printer produces fish ladder

As of this autumn, the Netherlands will have the first 3D printed fish ladder. The design has been optimised using simulation software for the required flow and choice of fish. 3D printing is the ideal way of producing the somewhat unusual shapes required.

Fish ladders are already frequently used to give fish access through the barriers we use to regulate water levels in our country. Movares consultants & engineers has now driven the design of such access ladders to a totally new level thanks to the FISHION fish ladder.

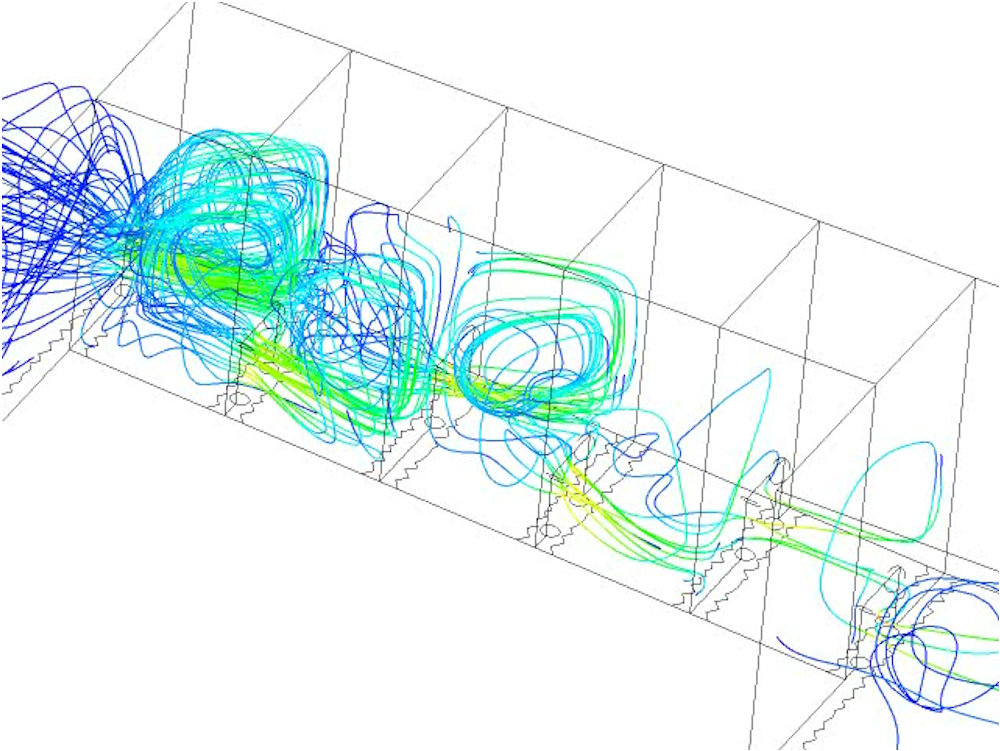

'We entered the water flow in the fish ladder into a hydrological model, which allowed us to modify the design to provide an optimal flow profile', explains Camiel Dijkers of Movares. 'At the same time, it calculated the volume of water flowing through the weir, as the weir or sluice is in the watercourse for a good reason. We don't want too much water flowing through the fish ladder.'

Full design freedom

The fish themselves were also modelled. 'We can now optimise the design for the species of fish we want to access the fish ladder.' The fish ladder may be primarily intended for eel, for example, and would then have a slightly different shape than one for bream.

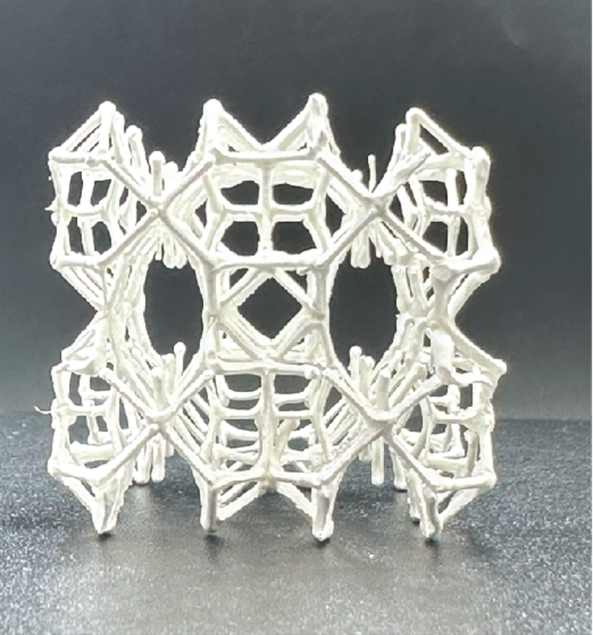

The modelling software doesn’t need to account for the practical feasibility of the final design, and that is where 3D printing comes into its own. 'That gives us virtually unlimited design freedom.'

The material used by the printer is polypropylene, reinforced with tiny glass fibres. 'After printing, we coat the fish ladder black in order to protect it against the effects of ultraviolet light, as that would make the material brittle.'

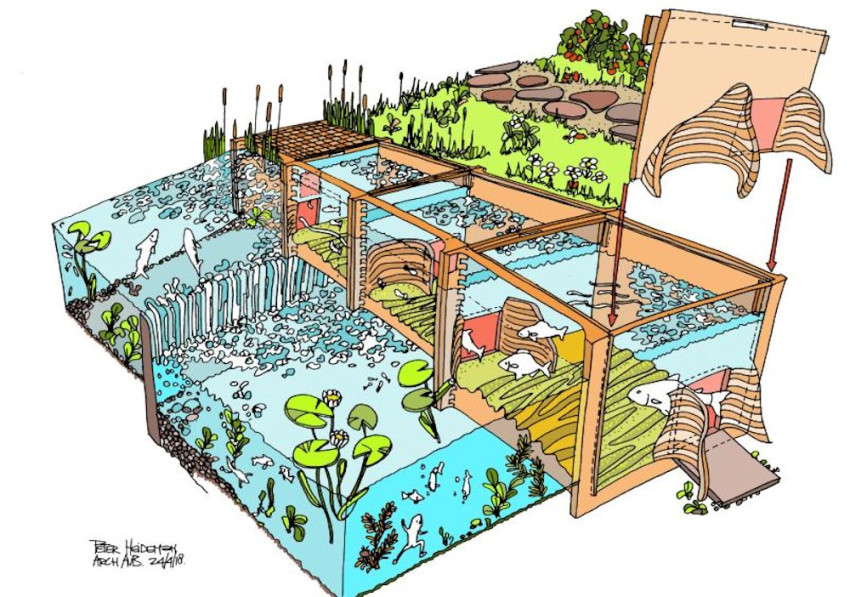

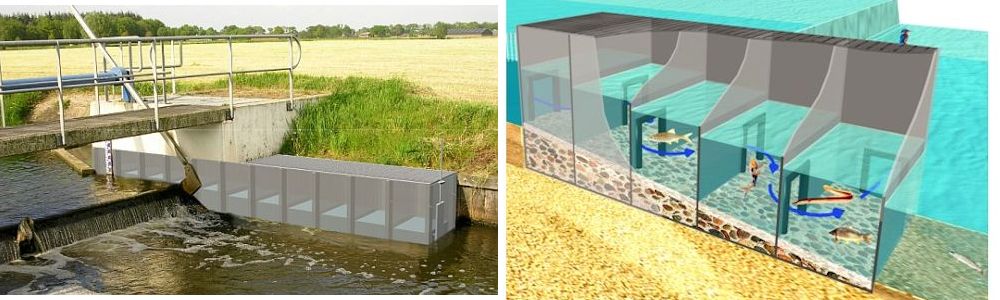

Movares based its fish ladder on a tried and trusted model by Wout de Wit. The fish ladder comprises a number of chambers with staggered openings (see the illustrations above). Each chamber bridges a height difference of around 5 cm. The fish swim against the luring flow to reach water higher up.

The advantage of that design is that a relatively small volume of water needs to flow through the ladder for it to work effectively. Moreover, the chambers offer fish the opportunity to rest before swimming upstream to the following chamber.

Modular build

Dijkers explains that the fish ladder has been constructed in modules. 'Each of these parts can be easily replaced without needing to demolish the complete fish ladder.' This allows simple adaptation of the fish ladder to new circumstances.

The first 3D printed FISHION fish ladder will be used by the Stichtse Rijnlanden regional water authority at Lopik this autumn.

Opening image: sketch of the modular 3D printed fish ladder. Illustration: Peter Heideman.

If you found this article interesting, subscribe for free to our weekly newsletter!