Failure trial of dike with sheet piling completed successfully

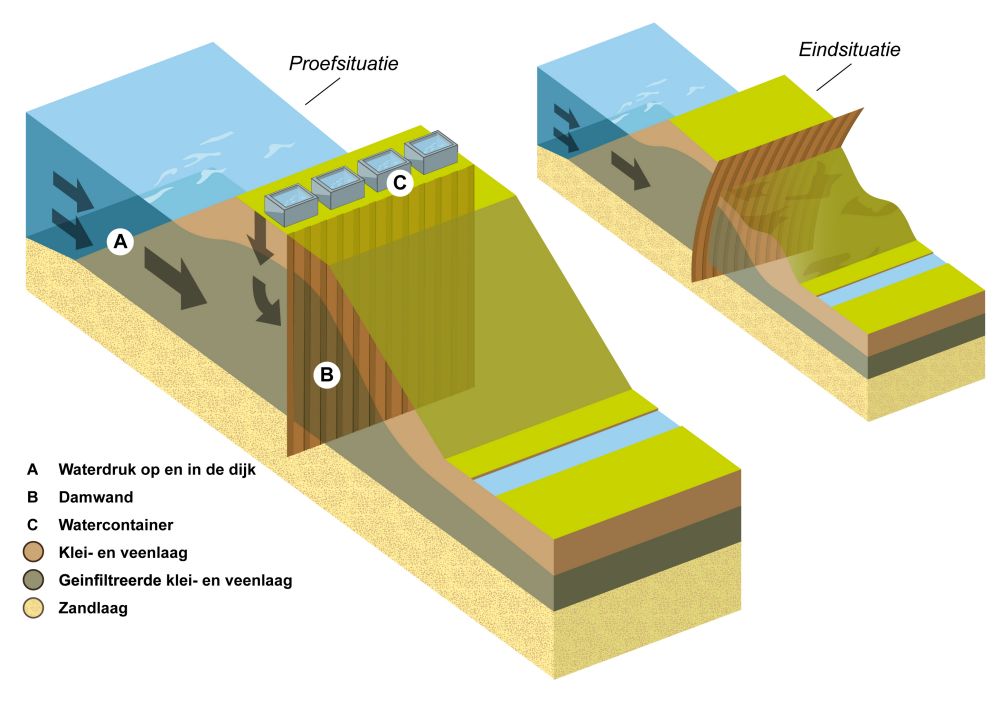

A dike with sheet piling successfully completed a fail-test near the village of Eemdijk. The trial was designed to provide insight into the interaction between the dike and the sheet piling, with the aim of using less heavy-duty sheet piling in future.

Sometimes, long steel sheet piles are fitted to a dike to further strengthen it. This is done when a dike does not meet the required standards or when there is insufficient room to widen it or build a secondary dike. Such sheet piling does a great job, but that's partly due to the extra-thick steel plates used. ‘Basically we don’t really know how the interaction between the ground and the sheet piling works,’ says Goaitske de Vries, Trial Coordinator and Technical Manager of the Hollands Noorderkwartier Water Authority. ‘It’s quite possible that we're using 20 to 30 percent more steel than is truly necessary.’

The trial is designed to illustrate whether using less steel still provides the same level of safety, as this could save tens of millions of euros. And the best way to study this is to load a dike with sheet piling until it fails. After all, if you know when the failure is going to occur, then you can find a solution to prevent it from happening. ‘The trial teaches us what forces the sheet piling can withstand.’ The trial is part of Rijkswaterstaat's POV Macrostabiliteit [Inter-project Exploration of Macro Stability] innovation programme.

Weak peat

The trial ultimately involved a dike with a 60 m long sheet-pile dam wall. The dike was constructed near the village of Eemdijk in the form of a small arena. ‘A subsoil of weak peat, a dike with a core of sand and a cover of clay corresponds with most river dikes.'

For the failure trial, the ‘dike arena’ was filled with water. ‘This emulates a high water level in a river.’ Furthermore, the dike was filled with water from the bottom, so that it gradually became saturated with water. On the ‘landside’, the bottom of the dike was tested further by digging a drainage ditch along its length. On top of the dike, containers were placed to further increase pressure.

The ‘landside’ of the dike eventually collapsed, which is one of the main mechanisms through which a river dike typically fails. ‘This lack of stability is precisely one of the problems that need to be resolved in terms of dike reinforcement.’ The sheet piling then buckled, giving the water free reign.

Forced collapse trial

Failure of the dike with sheet piling, was the final test in a series of trials. In the first trial, part of the dike without sheet piling was caused to fail. De Vries: ‘This gives us a baseline for the strength of a dike without sheet piling.’ Next, short sheet piles were fitted, which were pulled over using a hydraulic cylinder. ‘This gave us greater insight into the interaction between the sheet piling and the ground, and the way in which the sheet piling buckles.’

For this series of trials, the sheet piling was fitted with various sensors and other measuring instruments, to determine in detail the pore pressure in the dike, dislocation and deflection of the sheet piling, and the movement of the ground. ‘We are now faced with the task of analysing all the data,’ says De Vries.

If you found this article interesting, subscribe for free to our weekly newsletter!

Meer artikelen

Hoe gaat het met de energietransitie in Europa?

Martijn Otten: Met techniek het verschil maken

Martine Stam: Water is de rode draad in mijn leven

Nieuwste artikelen

Hoe gaat het met de energietransitie in Europa?