NAM launches storage project using compressed air together with Storelectric

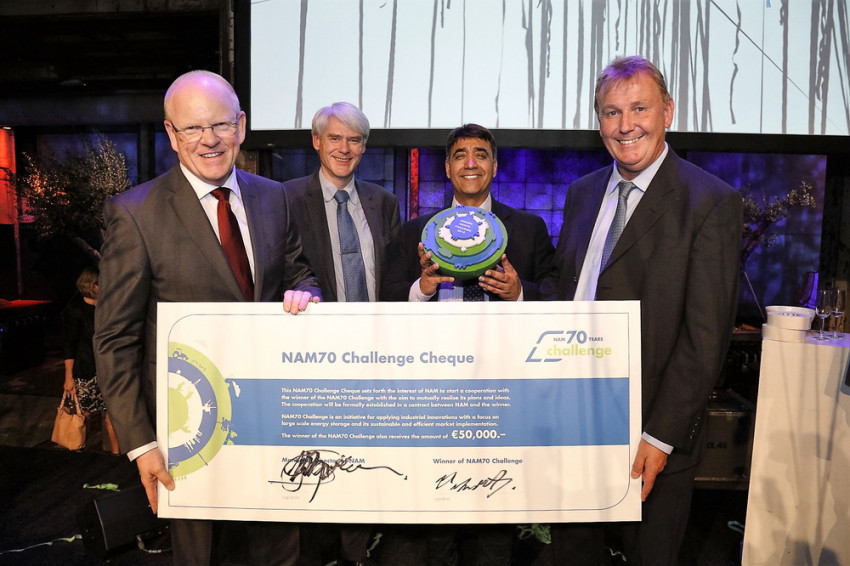

In collaboration with NAM, the English company Storelectric is planning to build a plant to store renewable electricity by compressing air. Storelectric was the winner of the NAM70 Challenge that the gas company organised to celebrate its 70th anniversary.

Storelectric uses an excess of renewable electricity to compress air and to store it in salt caverns or depleted gas and oil fields for example. If the electricity is needed again, the compressed air is used to power a generator.

This compressed air energy storage as such is not new – there is, for example, a compressed air power station in Huntorf, Germany. However, Storelectric has improved the storage technology by re-using the heat generated when the air was compressed to around 70 bar to re-heat and expand the air for generating electricity.

Efficient storage

Storelectric claims that an efficiency of 65% is achieved in the whole cycle, from electricity to compressed air and back to electricity again. ‘That makes our system the most efficient way of storing electricity over prolonged periods and in large quantities,’ says Tallad Azid of Storelectric. See below the pich of the storage using compressed air.

Storelectric currently has a trial project in England. In the Netherlands, the company is planning first and foremost to use salt caverns, large voids in salt layers where at present natural gas is stored, for example in Zuidwending. In time, storage in porous strata should also be possible. ‘A large number of such strata are available in the North Sea equipped with installations that used to drill for oil and gas and which now have to be dismantled. Use that infrastructure.’

Actual implementation

In addition to the cash award of 50,000 euros, the prize also means an agreement that NAM will actually implement the storage within three years, together with Storelectric. ‘It is essential for the future of our company that we pool our know-how with partners for the energy transition, and the storage of sustainably generated electricity is one of the biggest challenges here,’ says Schotman.

Heat storage

Two other finalists were Eco-Tech Ceram from France and the Dutch company, Proton Ventures. Eco-Tech has devised a method of storing residual heat for instance from industry or fermentation plants. Below 100°C, that can be most easily done in water, and at higher temperatures in ceramics with air, says Aubin Touzo from Eco-Tech Ceram.

But the place where the heat is released is generally not the place where it is needed. Transport is therefore necessary. In the Netherlands, that takes place for example, via a heating grid, but that infrastructure is expensive and generally has a limited temperature range. Eco-Tech stores the heat in the form of a container that can make use of all existing methods of transport. 1.5 MWh can be stored per container. As already mentioned, the concept can also be used to store heat from above 100°C to over 500°C by using ceramics.

The greatest difficulty according to Touzo, is making the heat available from flue gases or from the compressors that NAM currently uses to pressurise the gas. See below the pitch of the heat storage.

Ammonia

Proton Ventures uses existing technology to convert excess electricity into ammonia that is easy to store and transport. Ammonia has a vast array of applications. Engines can use ammonia as fuel, electricity can be generated when using it in a fuel cell, it serves as a raw material for fertilisers and it is easy to convert into hydrogen for a wide range of applications.

The advantage of ammonia compared with hydrogen is that it is far easier to use. For example, no heavy pressurised tanks are necessary for storage of the stuff. These are necessary with hydrogen in order to get sufficient volume. ‘Just as natural gas currently has a wide range of applications, that will be the case with ammonia in the future,’ says Jacco Mooijer from Proton Ventures. See below the pich of the ammonia storage.

The use of ammonia is not new. Vattenfall (Nuon), for example, is investigating the use of ammonia as fuel for its power station.

If you found this article interesting, subscribe for free to our weekly newsletter!

Opening photo: NAM CEO, Gerald Schotman, with the the team from Storelectric. Photo: NAM.