Monster machine for ships

The costs of maintenance and inspection of ships are substantial. But these costs are slashed by tens of millions of euros thanks to the hexapod, the ‘beast of Delft University of Technology’, presented last week.

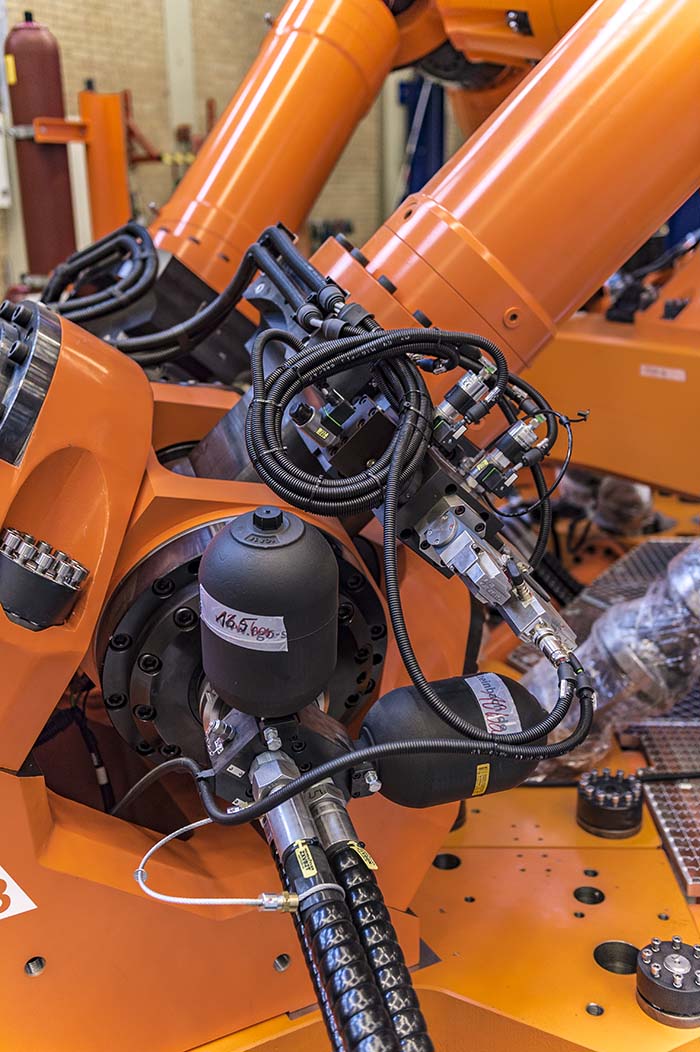

The sixty ton hexapod ‘shakes’ welded parts of ships to simulate the forces exerted by the waves. Within a month, this reveals symptoms of fatigue that normally only come to the surface after twenty years at sea. Ship designers can use this data to improve their designs.

‘We can now accurately compute at which spots a structure requires strengthening. And that saves material and makes a huge difference in maintenance costs,’ says the inventor of the device, prof. dr. ir. Mirek Kaminski. ‘For an extra design investment of a few million euros, these costs are slashed by tens of millions of euros over a 20-year period. This was demonstrated in a study we carried out recently together with the US Coast Guard.’

Rotating, tipping and shaking

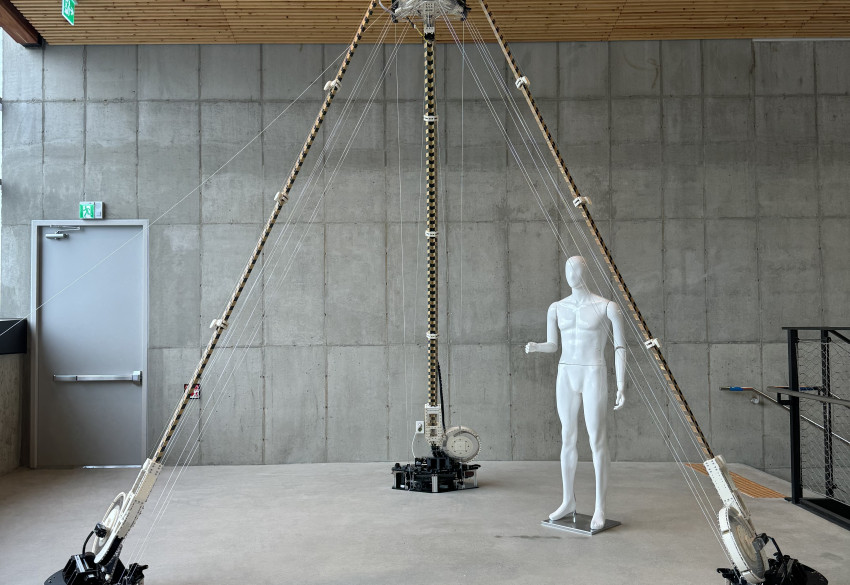

The hexapod, a room-filling device of 6 x 5 x 3 m, is a platform above which a ‘ceiling’ can rotate (twist) around a vertical axis, tip on two horizontal axes and move back and forth along three axes. That's possible using the six cylinders in the device. Ship parts are clamped between the platform and the ceiling, and are thus subject to forces up to 100 tons in six different directions.

The stresses arising in the material are measured by sensors under the platform. ‘The data is sent to a computational model that predicts fatigue symptoms,’ says offshore engineer ir. Paula van Lieshout, who is conducting doctoral research into a good computational model using the hexapod.

The hexapod is the first device in the world that exerts force on parts in six directions simultaneously. Until now, ship parts had to be subjected to tests on different test benches, with one for twisting and one for pulling, each with its own computational model to process the data. The results of the various models then had to be combined.

The result of this is a high level of uncertainty in the fatigue symptoms, the random application of extra reinforcing material and a lot of maintenance. Exerting forces in six directions simultaneously means that it's now possible to use a single model that calculates these problems. Van Lieshout is currently testing, selecting and refining computational models that can deal with the entire data package. ‘I hope to complete this study in early 2019.’

Wind turbines

Half of the funding for the hexapod was provided by Delft University of Technology, with 25% coming from the Dutch government and 25% from 23 companies, including Shell, Bluewater and Allseas. Kaminski expects that the (offshore) industry can use the first results of the hexapod in the course of 2019. ‘Shell wants to use them to design Deepwater Risers. And Allseas is going to produce pipe-laying ships and working vessels, such as the Pioneering Spirit, which lifts and moves drill rigs, using this device.’

Shipping owners may also be able to keep ships in service for longer. ‘Normally they are sent to the scrapyard after 20 to 25 years or are sold. Now, a well-designed ship might be good for 30 to 35 years, with just minimal maintenance costs in its later years.’ But there are benefits too for wind turbine and bridge builders and the aviation industry. ‘It's basically a universal device. It doesn't just simulate wave forces, but also forces from winds and currents and vibrations in the ground.’

That the hexapod can simulate material fatigue from twenty years of wave action in a month is not unique: the automobile industry already runs these simulations. The method goes roughly as follows: the parts are not exposed to motion at 0.1 Hz (the average frequency of a wave), but to 30 Hz. This ensures that the ship parts become ‘fatigued’ some 200 to 300 times faster than at sea. ‘That is why we need just one month's trial instead of 20 years. The only consequence of this is that heat is generated, but this is dispersed rapidly enough, up to a limit frequency of 30 Hz, that it has no effect. Beyond that, the heat effect becomes somewhat noticeable and the accuracy of the predictions decreases. But for steel, things really start to go wrong at around 100 Hz.’

If you found this article interesting, subscribe for free to our weekly newsletter!