Hydrogen battery trial at Nuon power station

Trials are going to be carried out with the battolyser at the Magnum power station, which is operated by the Nuon energy company. This is a device that can both store electricity and produce hydrogen, and will have a capacity of 60 kWh in this demonstration project.

What makes the battolyser special is that it combines two functions: electricity storage and hydrogen production by electrolysis. Fokko Mulder, professor at Delft University of Technology, developed the device to solve a dilemma in the renewable electricity supply. 'The discussion about the storage of renewable energy sometimes leans towards using batteries, and at other times towards converting it into hydrogen gas. Neither offers a perfect solution,' he told De Ingenieur in late 2016 when he got the first battolyser working. 'The problem with batteries is that a lot are needed to store all the energy generated at peak times. Hydrogen production, on the other hand, suffers from a different problem – the installation is only profitable during peak generation times, which in annual terms is not enough to make a return on the investment required. The other difference is that battery storage is mainly a short-term solution, while hydrogen is much more suited to seasonal fluctuations.'

Scaling

The solution is to combine both technologies in one device. The battolyser is used as a battery until it is fully charged, after which the device automatically switches to the production of hydrogen gas.

An initial demonstration project of 60 kWh is now being installed at the Magnum power station, thanks to a subsidy of €480,000 from the Wadden Fund. Nuon and fertiliser manufacturer Yara are also contributing to the development of the device. Delft University of Technology and Proton Ventures, a company specialising in energy storage, had already formed a partnership.

The battolyser will be commissioned early next year, and will then undergo extensive trials. If the results are positive, further scaling up to 1 or 10 MWh will follow.

Technology more than a century old

The battery’s electrodes are made of iron and nickel, with a potassium hydroxide solution as electrolyte. Mulder says, 'Nickel-iron batteries have been around for more than a century. They are very robust, but lost out to lead batteries.'

Part of the reason that nickel-iron batteries declined in popularity was that they also produced hydrogen – at the time an unwanted loss. 'We are now exploiting this characteristic to the full.' During charging, reduced iron and nickel oxide hydroxide are produced. These two materials are known in the electrolysis world as catalysts suitable for the production of hydrogen.

High efficiency

The battolyser offers some clear benefits when it comes to utilising sustainably generated electricity, according to Mulder. 'The battery function is the most efficient for quickly returning power. The battery then chooses the less efficient option: conversion of electricity into hydrogen gas by electrolysis.' This can then be stored until it is used to generate electricity again, or until it is used as vehicle fuel or for industrial processes. Incidentally, the efficiency of the electrolysis is up to 90%. 'That is relatively high,' according to Mulder.

If you found this article interesting, subscribe for free to our weekly newsletter!

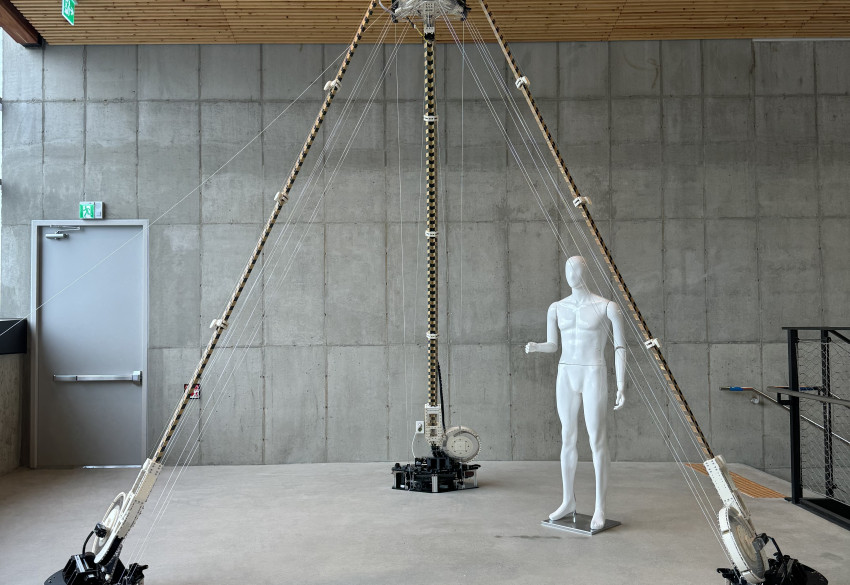

Illustration: Joost van Lierop.