Is this the future of construction sites?

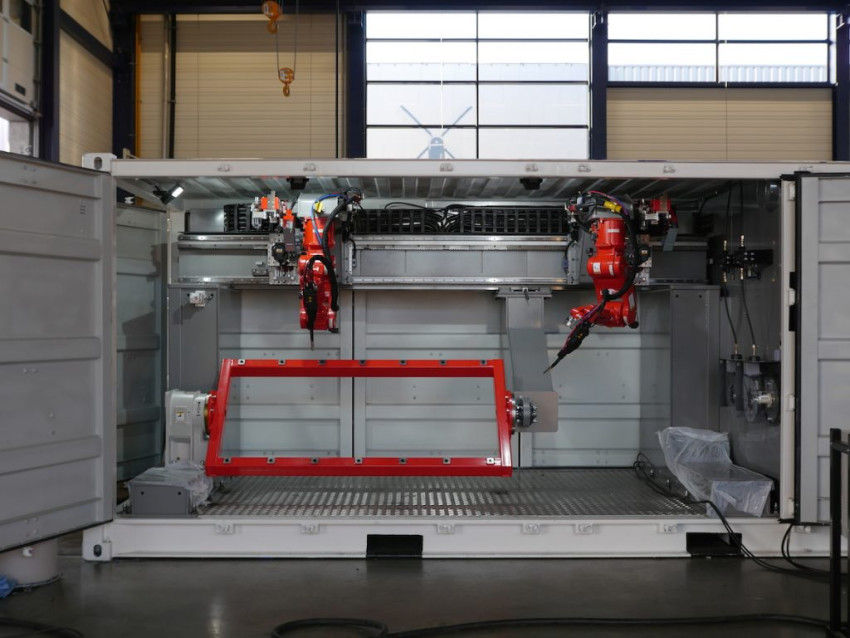

3D-design software maker Autodesk and construction company Dura Vermeer are showing us what we might find on the building site of tomorrow. At the largest Autodesk trade fair of the year, in Las Vegas, the companies presented a shipping container with welding and printing robots that functions as a mobile production facility.

The two strong robot arms from Panasonic in the container can be deployed for 3D-printing metals (using Directed Energy Deposition) and for welding. This means they can produce a wide variety of metal components on command at the construction site. All that's needed is a three-dimensional construction drawing of the required part, which is where the Autodesk design software comes in.

The container proves its worth especially with unusually shaped metal parts. Standard components are probably still best manufactured in bulk in a factory, using series production.

The container concept was showcased this week to visitors of the Autodesk University in Las Vegas, a trade fair that took place this week. Professionals employed by companies across the globe, in the fields of architecture, design and production, came together here. These sectors use the 3D-design software from the US firm.

PARTS

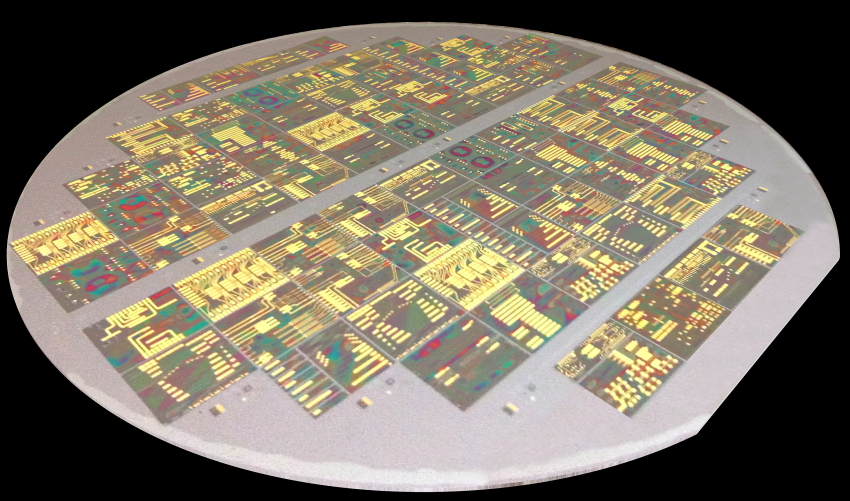

In a blog post, Autodesk gives a couple of examples of parts that the container can produce. Firstly, they show a customised ‘steel spider’ connector designed to keep a glass pane in place very accurately:

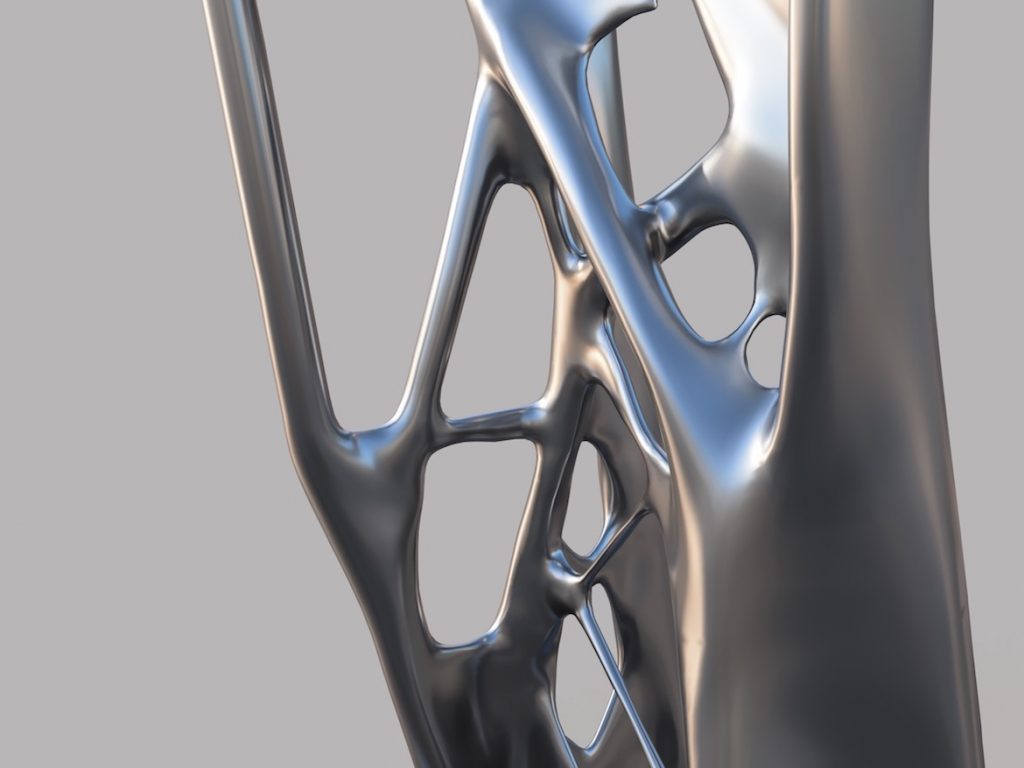

The second example that Dura Vermeer provided is a structural element that normally consists of ten separate parts. This in turn requires a chain of different suppliers, all with their own delivery times and ways of working. What if you could replace that element with an organically formed single-piece metal component? What's more, a part that you can manufacture on-site. The result looks great, or in the words of Autodesk: ‘has a higher architectural quality’:

And finally, the third example, a coupling piece that absorbs the forces from structural cables and rods at a connecting node:

It'll take a couple of years yet before such a container will actually be used in construction. The sector is often accused of being rather conservative. But these two companies are showing that innovation is still possible. We also see innovation in the concrete printing of structures.

TAKING A TRIP

The production container and the prototypes of Dura Vermeer are showcased this week at the Autodesk University in Las Vegas. After that, the prototype will travel to other trade fairs, in Europe. 'We would very much like to hear from other companies in the construction sector how they expect to use our technology,' says Autodesk in its blog post. Extra convenient: the container can be loaded onto a lorry.

If you found this article interesting, subscribe for free to our weekly newsletter!

Images: Autodesk / Dura Vermeer