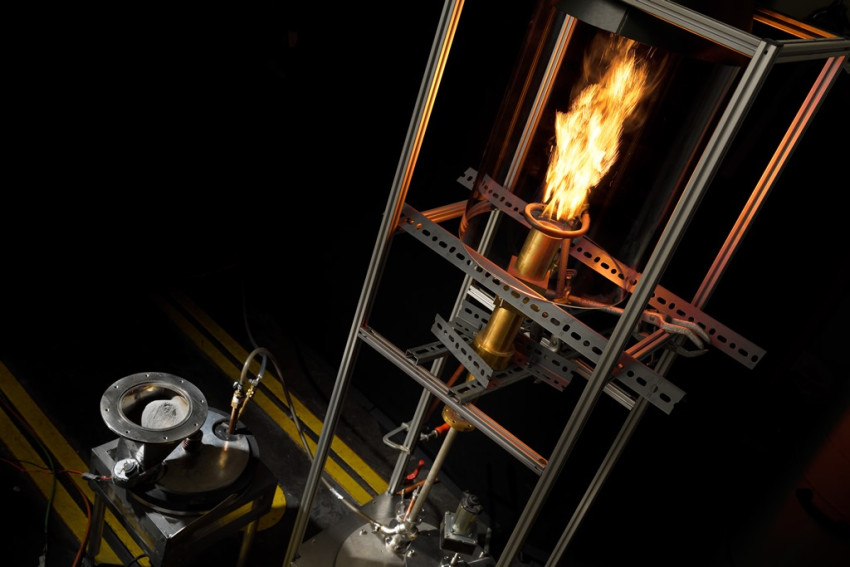

First system to use iron powder as fuel has been built

Students from Eindhoven University of Technology have built the first tech demo of a system that generates heat by burning iron powder. They hope to be able to further scale up this process, so that it can be used in industrial applications instead of burning gas or coal.

The students from Team SOLID have built a system with a capacity of 20 kW that burns iron powder and releases heat. This can be used to heat water or create steam, and to generate electricity via a Stirling engine.

The process can also be reversed to convert the iron-oxide powder (rust) made during the first step back into iron. This can be done using traditional non-eco-friendly processes, such as heating with coke, or using alternatives such as hydrogen. The latter is a much greener option, because hydrogen can be produced with sustainably generated electricity.

VERY SUITABLE

Why is iron so suitable for this process? ‘Firstly, iron has a high energy density, and burns at a high temperature of up to 1,800 °C. Some industrial processes need temperatures of up to 800 or 900 °C, which is way beyond the scope of heating air with electricity via heat pumps', says Geert Vergoossen of Team SOLID. Another advantage is that iron can be stored very stably for a longer period of time, as long as no oxygen can reach it.

The team believes that iron powder has potential as a fuel with zero CO2 emissions. However, there are a number of obstacles which still have to be overcome. For example, iron powder can be made with different shapes of grain, but it has not yet been determined which shape is most suitable. ‘There are elongated particles, for example, which are like tiny Mikado sticks. They burn really well, but it’s not easy to distribute them finely and transport them,’ says Vergoossen.

Another challenge the team has to deal with when scaling up is handling the emissions generated by the process. NOx is released at such high temperatures, and possibly also particulates, and both will have to be filtered.

UNKNOWN

The most important obstacle is perhaps the unfamiliarity of iron as fuel. Although some four universities around the world are carrying out research into metal fuels, it’s really unknown territory for the students. They are the first to actually build a demonstrator (a working installation), and will therefore have to acquire a lot of knowledge about the combustion process themselves.

Vergoossen: 'Iron powder burns very differently to gas or coal, so we’re going to model the combustion. That will allow us to play around with all kinds of parameters, such as the flow of iron powder, the grain size, and the addition of oxygen.' The team is being supported in this by research at Eindhoven University of Technology.

In addition, the team is carrying out extensive experimental research on the 20 kW demonstrator. But there are already plans in the pipeline for its successor – a 100-kW system, for which the team is still looking for industrial partners.

This video explains how the installation works:

If you found this article interesting, subscribe for free to our weekly newsletter!

Photos: Bart van Overbeeke / Eindhoven University of Technology