IJmuiden sees CO2-efficient steel process depart to India

Tata Steel is to build a plant in India that uses technology developed in the steel plant in IJmuiden.

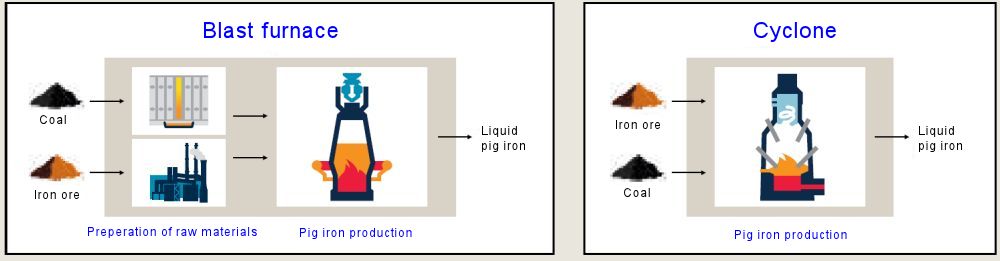

This relates to steel production using a cyclone furnace. Contrary to the traditional blast furnace process, a cyclone furnace requires far less preparation of the coal and iron ore, resulting in some 15% lower CO2 emissions with the cyclone process. The process can also use scrap or biomass, which leads to further CO2 savings, producing almost pure CO2 that is suitable for storage in the ground. A trial setup is currently running in IJmuiden that produces around 60,000 tons of pig iron annually. The new plant in the Indian city of Jamshedpur will have a capacity of 500,000 tons per year.

Intellectual property

Tata Steel announced the decision to go ahead with the investment last Friday in a discussion with Dutch journalists, reports Dutch newspaper de Volkskrant. The message was confirmed by the plant in IJmuiden. The decision was unexpected for the Dutch company: the technology for the cyclone furnace was invented in IJmuiden, the trial plant is located in IJmuiden, and all the necessary expertise is found in IJmuiden. But all the intellectual property is in the hands of Tata, which has the right to decide for itself where they locate the technology.

Merger with Thyssenkrupp

Undoubtedly, the coming joint venture of Tata Steel Europe with German steel producer ThyssenKrupp plays a role. That venture is awaiting approval by the European Commission, with a final decision expected on 19 March. Tata now wants to further develop the cyclone technology in its own backyard in India. This will require the deployment of experts from the Netherlands, states spokesperson Moens from the plant in IJmuiden.

Moens sees the Indian decision as recognition of the success of the cyclone technology. ‘It's a very good thing that this means a plant will be built there that is commercially feasible.’ According to him, the Indian decision does not mean that a larger plant will not be built in the Netherlands. Further decisions in this regard will be have to be taken by the new joint venture.

The origins of the cyclone furnace

The idea for using a cyclone furnace for the production of pig iron was conceived by Hoogovens in IJmuiden in the sixties. The furnace is called cyclone, because a rotating fluidized bed is created in which a hot gas melts the iron ore.

Trials in the sixties failed to properly produce pig iron in the cyclone furnace. But the idea was developed further in the eighties, when an existing converter was used to reduce the iron ore. At the start of this century, a collaborative operation followed with the British-Australian Rio Tinto, which developed a smelting technology to produce pig iron using oxygen and pulverized coal. This process turned out to be perfectly suited for addition to the cyclone furnace, and a trial plant was built that entered production in 2011. Initially to demonstrate that it was possible to produce pig iron, but subsequently to ensure further improvement of the technology.

Last year, a six-month reliability trial began, involving the construction of further systems for the continual supply of iron ore and pulverized coal. This reliability trial is still running.

If you found this article interesting, subscribe for free to our weekly newsletter!

Opening photo: transport of parts of the cyclone furnace in 2010. Photo: Corus.