Offshore test with water hammer

Together with a consortium of energy concerns and wind turbine fitters, start-up Fistuca is to carry out a major offshore test with its water hammer. This test is designed to demonstrate that a turbine foundation of 6.5 m in diameter can be pile driven into the seabed without making too much noise.

Last week, it was announced that Carbon Trust Offshore Wind Accelerator will be carrying out this major offshore test with Fistuca. Offshore Wind Accelerator is a collaboration of major energy concerns E.ON, EnBW, Ørsted (formerly Dong Energy), Equinor (formerly Statoil) and Vattenfall, together with industrial partners Van Oord (installation of wind turbines and laying of cables), Shell and Sif (producer of turbine foundations).

The aim is to use the water hammer to pile drive a steel hollow wind turbine foundation of 60 m long and 6.5 m in diameter into the bed of the North Sea, explained Jasper Winkes, CEO of Fistuca. ‘We will then be measuring the noise generated during piling both at the foundation pile itself and in the water.’

Hundred times less noise

The latter of these tests is what the water hammer is really all about. With normal piling, a fuel explosion provides the energy to drive the pile. Both the blow and the vibration of the pile cause such a high level of underwater noise that offshore wind turbine builders have to take special measures. For example, piling may only occur outside the migration routes of sea mammals, and a wide area around the piling plant must be declared free of sea mammals before piling can commence.

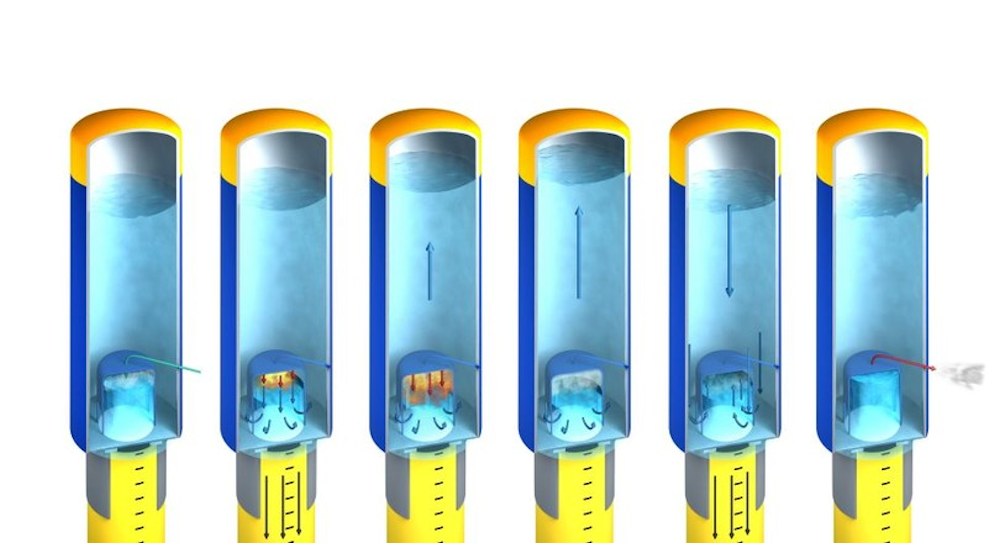

The water hammer also works using a gas explosion. However, this does not create the familiar piling thud, but pushes a sealed column of water downwards. This compression event provides the first blow. The water in the main chamber is then pushed upwards, only to fall down again, providing the second blow. Piling using water pressure generates much less noise and also causes less fatigue of the foundation pile, as the water spreads the blow over a longer period. The noise level is estimated to be 20 dB (a factor of 100) less than in normal piling installations.

Until now, Fistuca has been experimenting using a test model that performed to everybody's satisfaction. ‘Now we're going full scale,’ stated an upbeat Winkes.

Most powerful pile driver ever

The offshore project will be done using a water hammer that is much larger than the current test model: it will be 30 m high and 10 m in diameter. ‘This means we produce six times more piling energy than the biggest pile driver ever.’

The new hammer is to be tested initially on the Maasvlakte 2 area of the Port of Rotterdam. The plan is to carry out the offshore test this summer. The foundation pile is being supplied by Sif, with Van Oord doing the actual piling work at sea.

Opening image: animation of the largest water hammer in the Svaenen installation ship.

Photo: Van Oord.

If you found this article interesting, subscribe for free to our weekly newsletter!