Cleaner technique to extract oil from oil sands

Petroteq, a Canadian company, is to open a plant capable of producing oil cleanly from oil sands, in the US state of Utah next month. Chunks of sand will be processed in a tank containing a solvent, in order to extract the oil from the sand. The clean sand is then disposed of or can be used for building purposes.

Utah is known for its large reserves of oil. Until now however, mining was a difficult process. Petroteq believes it can remedy this situation. The Canadian company has developed a process that has already been tested on a small scale. Within a few weeks, a plant is to be opened that is designed to produce thousands of barrels of oil a day, at Asphalt Ridge, an area around 300 km east of Salt Lake City (see the map below), reports the New York Times.

Although this is only a drop in the ocean in the world of oil, the same plant is expected to produce five thousand barrels a day within three years. Petroteq estimates that the total parcel of land it has leased in Utah will be good for ten thousand barrels a day over a 25-year-period.

Evaporating solvent

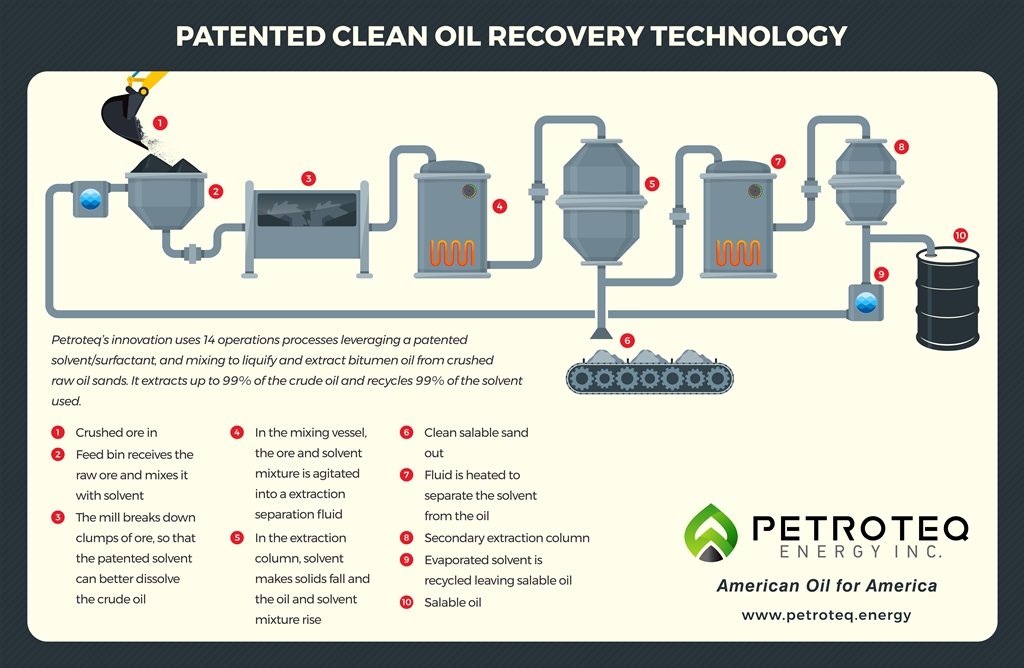

The new process is based on an organic solvent, the precise composition of which the company is unwilling to divulge. Chunks of the intensely black, oily earth and rocks are first ground down before adding the organic solvent to this mixture (see step 2 in the figure below). This mixture is then ground down even further (3) to ensure maximum contact between the oil sands and the solvent.

The main separation process takes place in the extraction column (5). Having dissolved in the solvent, the mixture floats up, while the heavier sand settles (6). After drying, this sand is suitable for disposal or sale. The oil and solvent mixture is then heated (7) to evaporate the solvent (and recycle it for reuse), leaving behind the oil (10).

If Petroteq manages to master this process, it will be the first company to successfully produce oil from oil sands in the US. Companies are already producing oil from oil sands on a large scale in Canada, but using a different method which is extremely polluting and uses large volumes of water. According to the Petroteq directors, their process does not require water, does not pollute the soil, and reuses all the solvent.

Environmental organisations

The company website actually refers to the reuse of ’99% of all solvents’. Minor fractions may possibly be left in the soil. Environmental organisations are therefore not happy with the company's plans. They fear that residual solvents will pollute the air or groundwater, thus affecting people or animals.

A second objection concerns the sand, as a by-product of the oil extraction process. If it is bone dry, as one might expect in the arid Utah climate, sand particles will be blown into the air and may fall upon the snowy, nearby mountains. Dirty snow absorbs sunlight much more than clean snow, and will therefore melt more quickly.

The company informed the New York Times that the sand would be kept wet precisely for this reason. That would not seem manageable once the process has been scaled up. It also seems to defeat the object of not using any water at all in this method of extracting oil.

Upscaling

Experts believe that the new Petroteq technology is theoretically workable. However, the company will first need to demonstrate the process on a larger scale in order to estimate its chance of success.

If you found this article interesting, subscribe for free to our weekly newsletter!

Opening photo: Photo taken by environmental activists, showing a deserted oil mining area in Utah. Liquid oil seeps from the ground here. However, oil sands are a type of black rock from which oil extraction is much more difficult. Source: BeforeItStarts / (CC BY-SA 2.0)