Battery stores thermal energy in concrete

A thermal battery was recently produced that uses concrete as a storage medium. This technology is particularly suitable for high-temperature heat of up to 450 °C.

Almost half of all the energy we consume is used to generate heat, and a large percentage of this has to be hotter than 100°C. This heat is usually generated by burning natural gas, which in the future could be replaced by green gas, hydrogen or nuclear energy. However, for this heat generation to be flexible, storage buffers are needed.

One solution is the thermal battery created by Norwegian firm EnergyNest, which can store heat of up to around 450 °C. Recently, a prototype of such a battery was produced at the Mebin concrete factory. A working test specimen of the thermal battery is already operating in Masdar City, a model city in Abu Dhabi. The battery has a capacity of about 400 kWh.

UNDERFLOOR HEATING

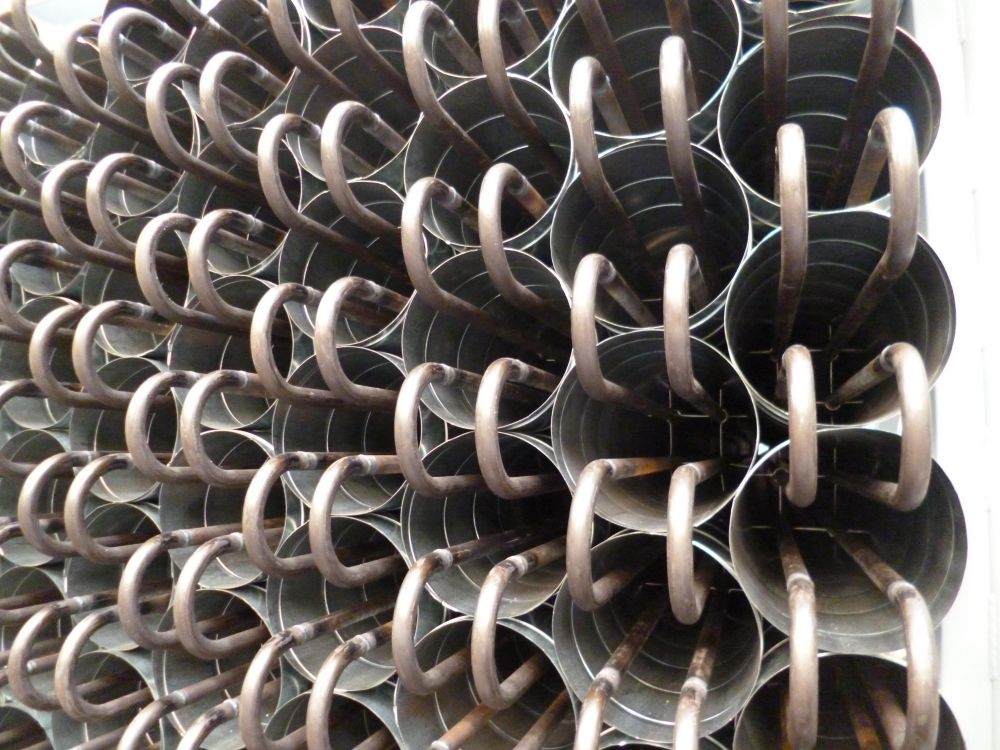

The idea behind the battery is simple. Embed a network of pipes in concrete, run hot liquid through them to heat up the concrete, then let the concrete heat up a cool liquid when heat is needed again.

However, the practical implementation also needs careful consideration. How do you make sure that heat is transferred as efficiently as possible? In addition, if the concrete has to handle temperatures of around 450°C, how do you prevent problems due to the material expanding and contracting?

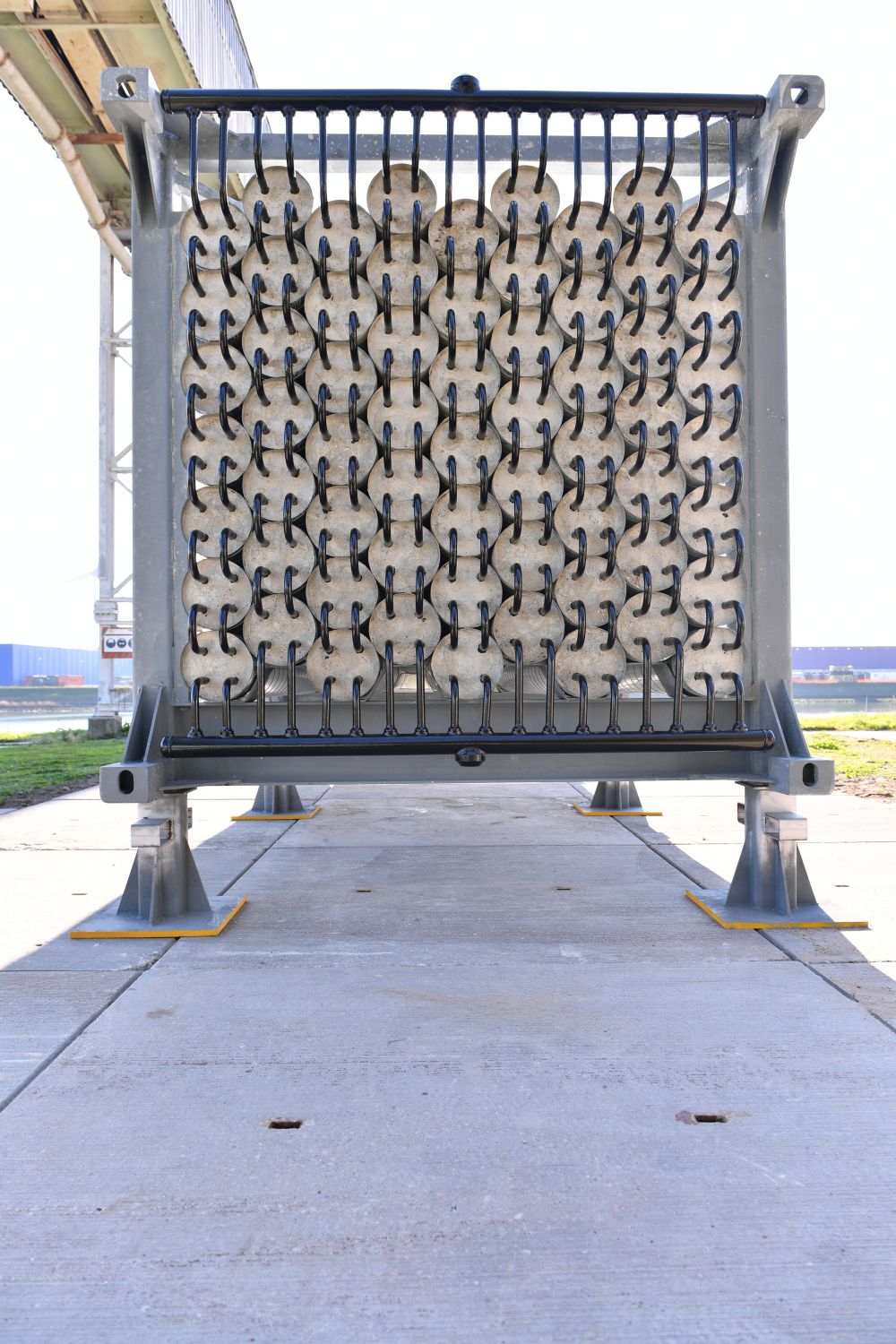

EnergyNest came up with an engineering solution that involves pouring concrete into tubes which are resistant to any kind of expansion and contraction. Each unit, which is the size of a 20-foot container, contains 63 of these tubes, which are laid in parallel over the length of the unit. In total, a unit contains about 16 to 17 m3 of concrete. Before the concrete is poured, four pipes are inserted into each tube for supplying hot liquid, or cold liquid to be heated up.

HEATCRETE

This is no ordinary concrete, but a special formulation developed for storing heat, and given the appropriate name Heatcrete. It was developed by HeidelbergCement, which owns Mebin.

'The concrete has to meet very special requirements,' says product manager Walter Speelman from Mebin. ‘It must withstand temperatures of around 450°C without any shrinkage cracks appearing. In addition, when the concrete is poured, the water balance has to be adjusted to prevent pores forming in the concrete.' According to Speelman, the parent company spent five years working on the concrete.

The material of the pipes embedded in the concrete was specially chosen so its coefficient of expansion is virtually the same as that of the Heatcrete. ‘Heat transfer is very efficient throughout the entire temperature range.'

EASILY SCALABLE

Since it is constructed in a container, the thermal battery is easily scalable: containers are placed next to or on top of one another, and the pipes connected. The capacity can vary from a few MWh for a single container to several GWh for a large complex.

To prevent heat losses, the container with the tube and pipe structure is insulated. EnergyNest claims that losses per day are about 2%, but this system is in any case intended for shorter periods of up to a week. The response time of the thermal battery varies from minutes to one hour, depending on the energy needed.

MEBIN – THE PREFERRED LOCATION

There are some very good reasons why Mebin's production location in Europoort Rotterdam was selected. Speelman: 'The battery in Abu Dhabi was made by transporting raw materials in big bags to Masdar City, and then producing the concrete on-site with a mobile installation. That was a one-off solution, so EnergyNest had to look for a suitable production location. The infrastructure in Rotterdam is designed to serve the whole world.

If you found this article interesting, subscribe for free to our weekly newsletter!